News

2022 / 05 / 13

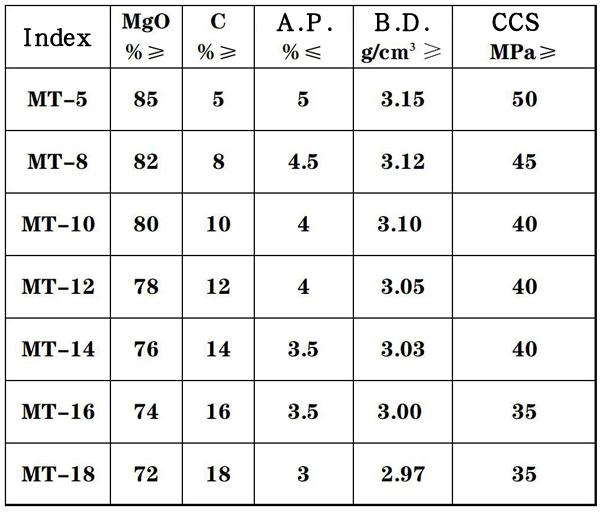

Magnesia-carbon bricks using on AC electric arc furnaces, DC electric arc furnaces, and ladle.

Magnesia-carbon bricks are made of high melting point alkaline oxide magnesia (melting point 2800°C) and high melting point carbon materials that are difficult to be infiltrated by slag as raw materials, and various non-oxide additives are added. Non-burning carbon composite refractory material combined with carbon binder. Magnesia-carbon bricks are mainly used for the lining of converters, AC electric arc furnaces, DC electric arc furnaces, and the slag line of ladle.

As a composite refractory material, magnesia carbon brick effectively utilizes the strong slag erosion resistance of magnesia and the high thermal conductivity and low expansion of carbon, which compensates for the biggest disadvantage of poor spalling resistance of magnesia.

Its main features are: good high temperature resistance, strong slag resistance, good thermal shock resistance, and low high temperature creep.

Preparation Process

Traditional magnesia-carbon bricks made with synthetic tar binders according to the cold mixing process harden and acquire the necessary strength during tar damage, thus forming isotropic glassy carbon. This carbon exhibits no thermoplasticity, which in time relieves substantial stress during liner baking or handling. The magnesia-carbon brick produced with pitch binder has high high temperature plasticity due to the formation of anisotropic graphitized coke structure during the carbonization of pitch.

Contact Us

Address

High-tech Industrial Development Zone, Zhengzhou City, Henan Province, China.

jean@ji-steel.com

Phone

+86 188 3804 2177

Products

- Continuous Casting

- ● Copper Mould Tube

- ● Mould Assembly

- Steel Melting

- ● Graphite Electrode

- Refractory Material

- ● Nozzle Bricks

- ● Magnesia Carbon Brick

- ● High Alumina Brick

Contact

- jean@ji-steel.com

- +86 371 6781 0168

- +86 188 3804 2177

- +86 188 3804 2177

- www.ji-steel.com

- High-tech Industrial Development Zone, Zhengzhou City, Henan Province, China.

Quick Links

© Copyright 2022 JI Steel. All right reserved.