News

2025/ 03 / 28

Precautions for using carbide roller rings

Carbide roller rings are high-hardness and high-wear-resistant tool materials composed of tungsten carbide and bonding metal. In order to make carbide roller rings fully play their advantages of high wear resistance, long life and high efficiency in high-speed wire rolling, high-speed wire manufacturers should pay attention to the following matters when purchasing and using carbide roller rings:

1. Correctly select the carbide grades used in each finishing mill

Before selecting the carbide roller ring grades used in each frame, you should fully understand the performance of each grade of carbide to meet the needs of matching the grades of each frame.

2. Installation of carbide roller rings

The sleeve and installation of carbide roller rings are strictly carried out according to the accuracy required by the design process. The roller rings and the frame roller shafts and taper sleeves require appropriate matching and cannot be too tight or loose. Before installing the machine, check whether the roller rings meet the process requirements, and the assembly surfaces of the roller rings, taper sleeves and shafts must be carefully cleaned. It is strictly forbidden to hit the roller rings with hammers or other hard objects during assembly.

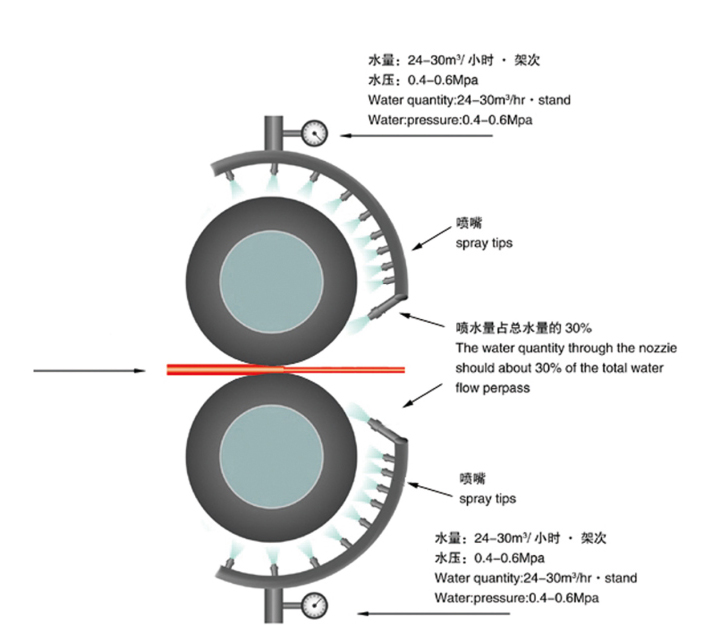

3. Requirements for cooling of roller rings and cooling water quality during rolling

When the roller ring is working, it is easy to produce network thermal fatigue cracks due to thermal corrosion, thermal fatigue and thermal stress. With the extension of thermal cracks, it will cause block peeling and even cause broken rollers in severe cases; cooling is to reduce the effects of thermal corrosion, thermal fatigue and thermal stress on the roller ring during rolling, prevent the roller ring from breaking, delay the spread of cracks, and extend the life of the rolling groove. It is very important for the effect of cemented carbide roller rings. The reference specifications for cooling are as follows: the temperature of cooling water is lower than 35℃, the pressure of cooling water is 0.4-0.6Mpa, the water volume is 24-30m3/hour, the water spray should be radial, and the angle with the rotation direction of the roller ring is 15-30°. The width of the water column is twice that of the rolling groove. It should be sprayed directly into the rolling groove. The water cannot be scattered or misty.

Cooling water quality requirements:

YGH series is suitable for neutral or weak alkaline water with pH ≥ 72

YGR series is suitable for slightly acidic water with pH ≥ 7.2 or pH ≤ 7.2

Solid particle content in water < 15 mg/L

4. Determine the reasonable rolling amount

It is inevitable that micro cracks will appear in the groove. After a certain period of rolling, the micro cracks will gradually expand, extend and deepen. When the depth reaches about 0.2-0.4mm, the machine should be taken off and ground immediately. Excessive rolling will cause the depth of micro cracks to expand rapidly, and the risk of broken rollers will increase, which should be prevented. The recommended normal rolling volume selection range is as follows:

Pre-finishing mill stand: (5000-7000) tons

Finishing 1-2 stands: (2000-3000) tons

Finishing 3-4 stands: (2000-3000) tons

Finishing 5-6 stands: (1500-2500) tons

Finishing 7-8 stands: (1500-2500) tons

Finishing 9-10 stands: (1200-2000) tons

Reducing and sizing mill stand: (1000-1500) tons

5. Groove grinding

It is difficult to avoid micro cracks in the roll ring groove during rolling. When the groove micro cracks reach a certain depth (generally controlled at about 0.2mm) during rolling, they must be removed and ground in time. This is necessary to reduce and avoid the continued expansion of micro cracks in the groove and cause broken rolls. When re-grinding the groove, it is necessary to completely grind away the micro cracks, otherwise the micro cracks that have not been completely ground away will bring great risk of broken rolls in the next rolling; it is difficult and inconvenient to use instruments to detect whether the micro cracks are completely ground away during grinding. In order to ensure that the micro cracks are completely ground away, a certain amount of grinding can be added. Under normal process rolling volume, grinding is generally controlled within:

Finishing mill (9-10) frame roller ring (0.4-0.6) mm

Finishing mill (1-8) frame roller ring (0.7-1.2) mm

Pre-finishing mill roller ring (1.2-2.0) mm

Contact Us

Address

High-tech Industrial Development Zone, Zhengzhou City, Henan Province, China.

jean@ji-steel.com

Phone

+86 188 3804 2177

Products

- Continuous Casting

- ● Copper Mould Tube

- ● Mould Assembly

- ● Ladle And Tundish Nozzle

- Steel Melting

- ● Graphite Electrode

- ● CPC/GPC

- ● Continuous Casting Protecting Slag

- ● Furnace Lining Vibrator

- Rolling Mill Equipment

- ● Steel Roll

- ● Tungsten Carbide Roll Ring

- ● Rolling Mill Guides

- ● Roller Table

Contact

- jean@ji-steel.com

- +86 371 6781 0168

- +86 188 3804 2177

- +86 188 3804 2177

- www.ji-steel.com

- High-tech Industrial Development Zone, Zhengzhou City, Henan Province, China.