News

2024/ 09 / 25

Analysis and Prevention of Electrode Breakage in Ladle Refining Furnace

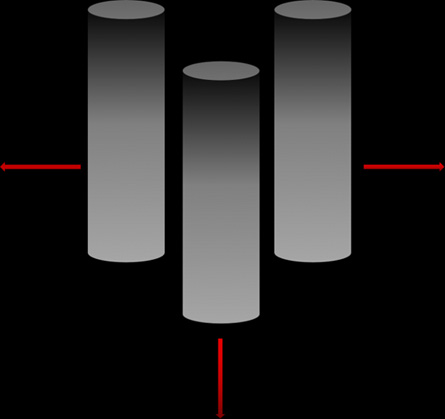

In the ladle refining process, graphite electrodes heat molten steel for thermal compensation. The consumption of electrodes accounts for 15% to 20% of total production costs. With fluctuations in electrode prices, this consumption can increase significantly. The loss from broken electrodes is substantial, leading to difficulties in handling, increased labor intensity, potential production interruptions, and even safety accidents. Thus, minimizing electrode breakage is crucial.

1. Causes of Electrode Breakage

Electrode breakage primarily occurs at weak points, like joints, due to mechanical forces.

2.1 Formation of Weak Points

Electrodes are composed of 2 to 3 segments connected by threads. Discontinuities at these joints reduce their bending strength. Transport and installation can cause visible or invisible defects, further weakening the joints and increasing breakage risk. Poor installation can create gaps at connections, increasing contact resistance and leading to overheating and erosion.

2.2 Mechanical Forces on Electrodes

2.2.1 Electrodynamic Forces During Melting

In the ladle refining process, electrode systems experience enormous currents, creating strong electrodynamic forces that can lead to vibrations and potential resonance, causing fatigue and breakage.

2.2.2 Effects of Slag Layer

The slag layer’s viscosity significantly impacts electrodynamic forces. If too viscous, it can disrupt electrode immersion and increase breakage risks.

2.2.3 Other Mechanical Forces

Electrodes can break due to external impacts during operations, especially when equipment is misaligned or obstructed.

Preventive Measures

3.1 Protection Before Installation

Ensure careful handling to avoid collisions, and verify that lifting equipment is secure.

3.2 Correct Installation

Clean electrode joints before installation, avoiding any gaps. Consider using spring-dampened lifting devices for added protection.

3.3 Operational Procedures

3.3.1 Handling Slag Shells

Break slag shells with high-pressure argon to promote even distribution of slag.

3.3.2 Stable Arc Ignition

Start with low currents for smooth arc ignition before increasing to normal levels.

3.3.3 Controlling Argon Injection

Monitor argon flow to ensure effective mixing without excessive impact on electrodes.

3.3.4 Minimizing External Forces

Avoid introducing oversized materials and regularly check for obstructions.

The main reason for graphite electrode breakage during production in the ladle refining furnace is the influence of various internal and external mechanical forces. By ensuring proper protection before electrode installation, correct installation, optimizing refining operations—especially stabilizing arcing and slagging conditions at the early stages of refining—ensuring slag condition and bottom-blown argon control meet refining requirements, and timely maintenance of equipment, electrode breakage accidents can be prevented.

Contact Us

Address

High-tech Industrial Development Zone, Zhengzhou City, Henan Province, China.

jean@ji-steel.com

Phone

+86 188 3804 2177

Products

- Continuous Casting

- ● Copper Mould Tube

- ● Mould Assembly

- Steel Melting

- ● Graphite Electrode

- Refractory Material

- ● Nozzle Bricks

- ● Magnesia Carbon Brick

- ● High Alumina Brick

Contact

- jean@ji-steel.com

- +86 371 6781 0168

- +86 188 3804 2177

- +86 188 3804 2177

- www.ji-steel.com

- High-tech Industrial Development Zone, Zhengzhou City, Henan Province, China.

Quick Links

© Copyright 2022 JI Steel. All right reserved.