News

2025/ 08 / 15

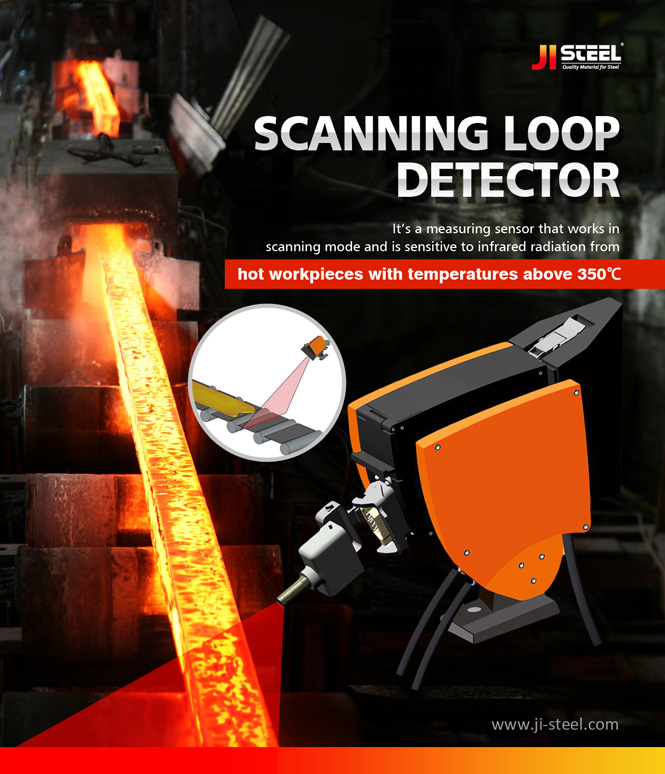

Intelligent Sensing Technology Empowers Steel Production: Innovative Applications of Loop Scanners in Modern Steel Mills

As China’s steel industry rapidly transitions toward intelligent and high-efficiency production, loop scanners (also known as loop height detectors) are facing important opportunities for technological upgrades and application expansion as critical inspection equipment. Latest industry data indicates that China’s intelligent manufacturing industry is expected to exceed 4 trillion yuan by 2025, with steel industry intelligent transformation investments accounting for a significant proportion. In this context, loop scanners integrating advanced technologies such as infrared detection and intelligent algorithms are evolving from single-function position detection devices into intelligent sensing terminals combining data collection, process analysis, and quality control, providing key technical support for steel enterprises to achieve “lights-out factories.” This article provides a comprehensive analysis of the latest technological advances, typical application scenarios, and future development trends of loop scanners.

Technology Upgrade: From Basic Detection to Intelligent Sensing

As the “eyes” of steel rolling production lines, the core function of loop scanners is to monitor the position and shape of hot metal in real-time through non-contact methods, providing critical data for loop height control in continuous rolling units. Traditional devices mainly relied on single infrared detection technology, while new-generation products are achieving performance leaps through multi-technology integration. The latest research report from Tsinghua University’s Technology Transfer Institute shows that modern loop scanners now commonly integrate three core technology modules: high-sensitivity infrared detection, laser-assisted positioning, and embedded intelligent algorithms, with detection accuracy improved to ±0.5mm and temperature detection range extended down to 200°C.

In terms of infrared detection, the IS-3000-LS series from American company ASC employs wide dynamic range infrared sensors combined with automatic gain control circuits, capable of adapting to full-process temperature variations from furnace exits (1200°C) to finishing mill areas (250°C). DELTA’s newly released Rota-Sonde TS5600 innovatively introduces dual-band infrared detection technology, optimizing sensitivity for both high and low temperature zones respectively, solving the industry challenge of unstable signals in temperature transition areas with traditional equipment. Notably, some high-end models have begun incorporating thermal imaging functionality, capable of detecting metal positions while simultaneously acquiring temperature distribution data, providing more dimensional information for process optimization.

The empowerment of intelligent algorithms represents another highlight of current technological upgrades. According to procurement technical specifications disclosed by Shenyang University of Technology’s Intelligent Detection Center, new-generation loop scanners generally feature built-in edge computing modules that can process raw detection data in real-time, automatically compensate for signal interference caused by steam and scale, and gradually optimize detection parameters through self-learning algorithms. This localized intelligent processing capability significantly reduces dependence on host computers, shortening system response time from the traditional 50ms to within 10ms, making it particularly suitable for high-speed rolling scenarios.

The concept of modular design is also profoundly influencing the development of new-generation products. Leading manufacturers’ loop scanners mostly adopt plug-and-play functional module designs, allowing users to select laser ranging, visual assistance, or wireless communication modules according to actual needs. Heavy industry intelligent transformation research reports indicate that this flexible configuration approach enables a single device to meet various application scenarios, significantly reducing users’ total cost of ownership. For example, laser ranging modules can be added for 3D profile scanning in strip rolling, while communication modules can be enhanced for multi-device coordination in bar and wire rod production.

Application Deepening: From Loop Control to Full-Process Quality Assurance

The traditional application of loop scanners focused on loop height control in continuous rolling units. With technological advances, their application scenarios are continuously expanding across the entire steel production process, forming a diversified application ecosystem. The China Iron and Steel Association’s 2025 technology research report shows that loop scanners currently demonstrate unique value in four major scenarios:

In loop height control, application practices at Xinjiang Bayi Steel show that after adopting high-precision loop scanners, loop height fluctuations in small and medium-sized bar rolling were reduced from ±15mm to ±5mm, with the resulting improvement in dimensional accuracy increasing product yield by 1.2 percentage points. The latest case shows that a large steel mill deployed a scanning system with AI dynamic compensation function in high-speed wire rod production, maintaining stable loop control even at rolling speeds of 105m/s, completely solving the “loop throwing” problem in high-speed conditions.

Strip centering control is another important application area. Traditional mechanical edge detection devices are prone to high-temperature deformation in hot continuous rolling environments, while infrared-based loop scanners demonstrate clear advantages. DELTA technical experts explain that its TS series products achieve ±1mm edge detection accuracy in strip rolling through 30° narrow-angle scanning mode, reducing strip deviation accidents by over 90% when combined with advanced control systems. Particularly noteworthy is that some specialized models developed by manufacturers can simultaneously detect strip width variations, providing real-time feedback for process adjustments.

In special steel rolling, the technical adaptability of loop scanners has been fully verified. Patents publicly disclosed by TISCO Group in 2025 show that its developed inclusion analysis system for clean steel innovatively combines loop scanning technology with machine learning algorithms, reducing scanning and analysis time per sample from 30 hours to within 4 hours—an 85% efficiency improvement. For special materials like stainless steel and silicon steel, equipment manufacturers have effectively overcome detection deviations caused by material emissivity differences through optimized optical filtering and algorithm compensation.

Breakthrough applications in low-temperature finishing areas are particularly noteworthy. Traditional views held that loop scanners were only suitable for high-temperature areas, but actual test data from the KDD-LH series products overturned this perception. A joint-venture automotive sheet plant deployed high-sensitivity scanners behind finishing mills at 250-400°C, successfully achieving precise tracking of low-temperature strips, replacing high-failure-rate contact detection devices and reducing annual maintenance costs by 600,000 yuan.

Intelligent Upgrade: Data Fusion and System Integration

Driven by industrial internet and artificial intelligence technologies, loop scanners are transforming from independent inspection devices into intelligent sensing nodes, creating greater value through data fusion and system integration. Research from Tsinghua University’s Intelligent Sensing Technology team indicates that modern loop scanning systems have developed a three-level intelligent architecture: adaptive detection at the device level, data fusion at the network level, and intelligent decision-making at the application level.

At the device level, the latest products generally feature self-diagnosis and predictive maintenance functions. Case studies from American company ASC show that vibration and temperature sensors built into their scanners can monitor device status in real-time, combining algorithm models to provide early warnings of potential failures, extending mean time between failures (MTBF) to over 50,000 hours. DELTA’s TS series generates maintenance recommendations by recording operational parameter trends, significantly reducing unplanned downtime risks.

In terms of data fusion, leading steel enterprises have begun building multi-source information sensing networks centered on loop scanners. An intelligent transformation project at a central state-owned steel mill synchronously analyzes scanner data with rolling mill current and rolling force information, establishing correlation models between loop height, rolling tension, and product dimensions, improving product thickness tolerance control capability by 40%. Latest research results published in scientific reports show that combined with improved Faster R-CNN algorithms, loop scanning images can be used for early identification of surface defects, achieving quality control at earlier stages.

At the system integration level, the combination of loop scanners and digital twin technology is becoming a new trend. In a digital twin project at a Jiangsu steel mill, scanner data drives virtual production line models in real-time, allowing process engineers to simulate parameter adjustment effects in virtual environments, significantly shortening trial production cycles for new steel grades. The project leader explained that this “sensing-simulation-optimization” closed-loop model reduces product development costs by 30% and increases trial production success rates to over 95%.

Notably, with the popularization of 5G technology, the wireless and edge computing capabilities of loop scanners are rapidly improving. Heavy industry scanner selection guidelines reveal that high-end models newly launched in 2025 generally support 5G/Wi-Fi 6 dual-mode transmission, enabling processed data to be directly pushed to cloud platforms, freeing them from traditional wired connections. Meanwhile, some products have begun integrating lightweight AI models to complete data cleaning and feature extraction at the device end, uploading only valuable result data, significantly reducing network bandwidth requirements.

Selection Strategies and Future Trends

Faced with diverse loop scanner products on the market, steel enterprises need to establish scientific selection evaluation systems. Combining industry expert recommendations and practical application experience, selection should focus on the following five dimensions:

Environmental adaptability is a basic consideration. Heavy industry scenarios commonly present challenges like high temperature, dust, and vibration, requiring equipment to meet operating temperature ranges of -30°C to 70°C and IP68 protection ratings. Comparative tests at a copper processing enterprise showed that in 60°C environments at casting workshops, products meeting these standards had failure rates only one-fifth that of ordinary equipment. Cooling system design is also crucial, with water cooling plus air purge combinations effectively addressing extreme thermal radiation near rolling mills.

Detection performance directly affects control effectiveness. Beyond conventional position detection accuracy, parameters like response speed and temperature detection range must match production processes. High-speed wire rod rolling requires response times <20ms, while strip rolling emphasizes ±1mm positioning accuracy. Notably, some new models offer multi-target tracking functionality, capable of simultaneously detecting multiple loops or strip edges, supporting complex control strategies.

Intelligence level determines long-term value. Equipment with self-learning and adaptive capabilities can reduce debugging difficulty and continuously optimize with process changes. A steel mill technical manager stated that scanners supporting automatic parameter tuning reduced new production line debugging cycles by 60%. Meanwhile, rich diagnostic interfaces and predictive maintenance functions can significantly lower total lifecycle costs.

System compatibility affects integration efficiency. Modern loop scanners should provide multiple communication interfaces supporting industrial protocols like PROFINET and EtherNet/IP for easy integration into factory automation networks. Some advanced models also offer open APIs supporting customized development of specialized functions.

Service support systems are often overlooked but crucial, including localized technical support, spare parts supply, and software upgrade services. Industry research shows that quality services can improve equipment utilization by 15-20%, especially important for small and medium steel mills lacking professional maintenance teams.

Looking ahead, loop scanning technology will evolve in three directions: first, multi-sensor fusion, combining lasers, vision and other sensing methods to provide richer quality information; second, deep AI empowerment, achieving more intelligent defect recognition and process optimization through deep learning algorithms; third, cloud-edge collaboration, enabling cross-production line and cross-factory knowledge sharing and coordinated optimization through industrial internet platforms. According to the “2025-2030 China Loop Scanner Industry Report,” the annual compound growth rate of intelligent loop scanners is predicted to reach 18.7% in the next five years, far exceeding traditional products and becoming an important driver for steel mill intelligent transformation.

As China’s steel industry moves toward high-quality development, loop scanners—as critical links connecting the physical world with digital systems—will see their value transcend mere inspection tools to become core components of intelligent manufacturing ecosystems. Steel enterprises should fully recognize this trend, adopting more forward-looking perspectives in equipment selection and applications, driving quality improvements and efficiency transformations through technological innovation.

Contact Us

Address

High-tech Industrial Development Zone, Zhengzhou City, Henan Province, China.

jean@ji-steel.com

Phone

+86 188 3804 2177

Products

- Continuous Casting

- ● Copper Mould Tube

- ● Mould Assembly

- ● Ladle And Tundish Nozzle

- Steel Melting

- ● Graphite Electrode

- ● CPC/GPC

- ● Continuous Casting Protecting Slag

- ● Furnace Lining Vibrator

- Rolling Mill Equipment

- ● Steel Roll

- ● Tungsten Carbide Roll Ring

- ● Rolling Mill Guides

- ● Roller Table

Contact

- jean@ji-steel.com

- +86 371 6781 0168

- +86 188 3804 2177

- +86 188 3804 2177

- www.ji-steel.com

- High-tech Industrial Development Zone, Zhengzhou City, Henan Province, China.