Products

Graphite Electrode

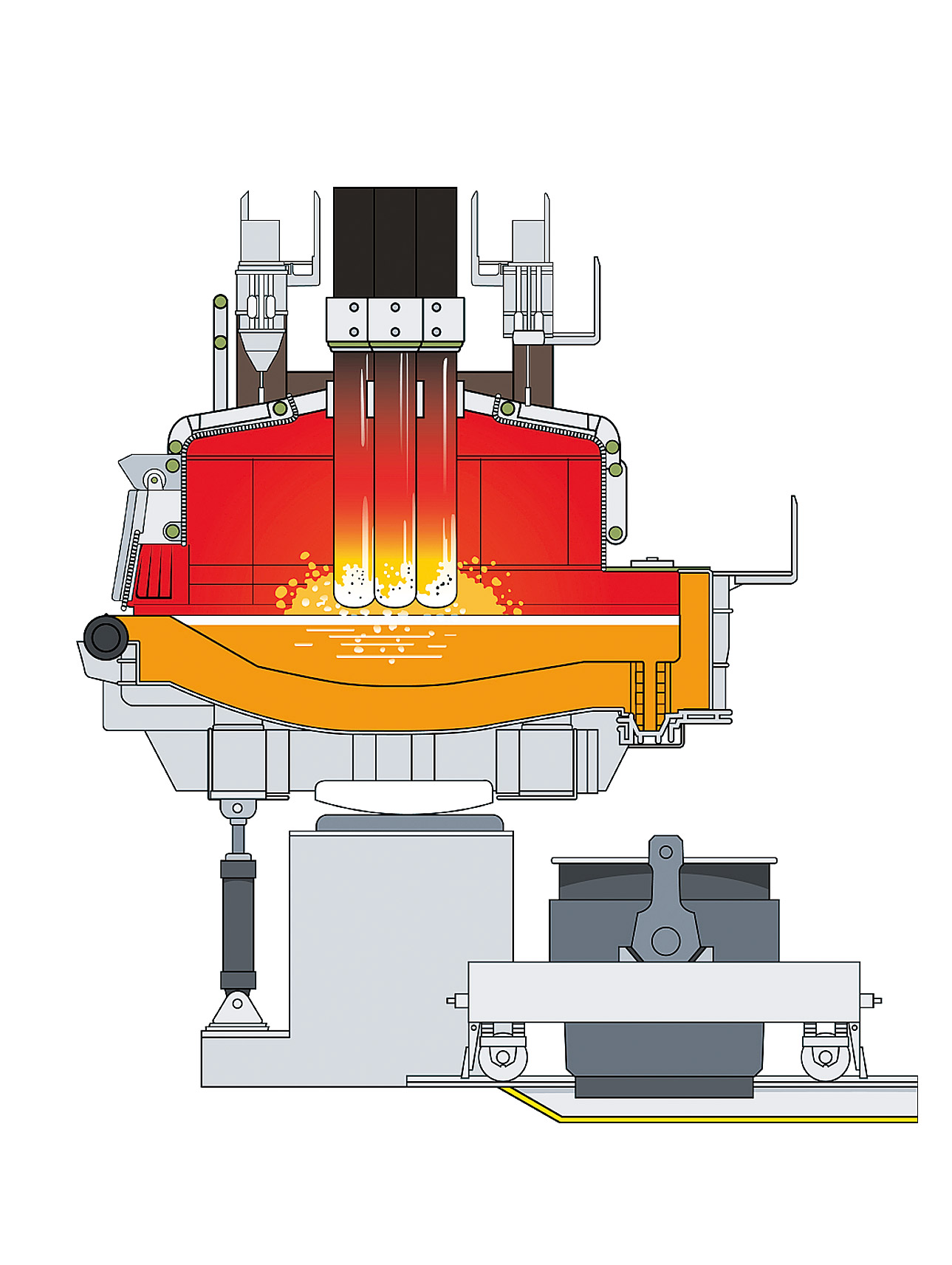

Using coal pitch as binder, the graphite electrode which is mainly made of petroleum coke and needle coke is being made through the process of calcination, compounding, kneading, pressing, baking,impregnation, graphitization and machining. It is a conductor that release electrical energy to heat and melt the charge in the form of an electric arc in an electric arc furnace, and has the characteristics of low electrical resistivity, good electrical conductivity, low ash content, uniform structure, good oxidation resistance and high mechanical strength.

Product Information

- Materials: Needle coke,CPC,Coal Pitch;

- Process: Petroleum coke calcined,Crush,Forming,Baking,Graphited,Machining;

- Grades: RP/HP/SHP/UHP;

- Application: Used in EAF/LF to make ste.

Product Features

- High temperature strength

- Low thermal expansion

- Excellent thermal and electrical conductivity

- Appropriate machinability

Technical Data

| Item | Unit | Graphite Electrode | ||||

| RP | HP | UHP | ||||

| φ100-φ700mm | φ100-φ700mm | φ200-φ500mm | φ550-φ700mm | |||

| Typical Value | Typical Value | Typical Value | Typical Value | |||

| Resistivity | Electrode | μΩm | 7.0-10.0 | 5.8-6.6 | 4.5-5.8 | 4.6-5.8 |

| Nipple | 4.0-4.5 | 3.5-4.0 | 3.5-4.0 | 3.5-4.0 | ||

| Modulus of Rupture | Electrode | Mpa | 8.0-10.0 | 10.0-13.0 | 10.0-14.0 | 10.0-14.0 |

| Nipple | 19.0-22.0 | 20.0-23.0 | 20.0-24.0 | 22.0-26.0 | ||

| Young’s Modulus | Electrode | GPa | 7.0-9.3 | 8.0-12.0 | 9.0-13.0 | 10.0-14.0 |

| Nipple | 12.0-14.0 | 14.0-16.0 | 15.0-18.0 | 16.0-19.0 | ||

| Bulk Density | Electrode | g/cm3 | 1.53-1.56 | 1.64-1.68 | 1.68-1.74 | 1.70-1.74 |

| Nipple | 1.70-1.74 | 1.75-1.80 | 1.78-1.82 | 1.80-1.84 | ||

| CTE (100-600℃) | Electrode | 10-6/℃ | 2.2-2.6 | 1.6-1.9 | 1.1-1.4 | 1.1-1.4 |

| Nipple | 2.0-2.5 | 1.1-1.4 | 0.9-1.2 | 0.9-1.2 | ||

| Ash | % | 0.5 | 0.3 | 0.3 | 0.3 | |

Physical Dimension of Electrodes

| Nominal Diameter | Actual Diameter | Nominal Length and Tolerance | |||||||||||

| Max | Min | Min. Crust Diameter | 1500 | 1800 | 2100 | 2400 | 2700 | ||||||

| Standard | Short | Standard | Short | Standard | Short | Standard | Short | Standard | Short | ||||

| 150 | 154 | 149 | 146 | ±100 | – 225 | ±100 | – 275 | ||||||

| 200 | 205 | 200 | 197 | ||||||||||

| 250 | 256 | 251 | 248 | ±125 | – 275 | ||||||||

| 300 | 307 | 302 | 299 | ||||||||||

| 350 | 357 | 352 | 349 | ±125 | – 275 | ||||||||

| 400 | 409 | 403 | 400 | ||||||||||

| 450 | 460 | 454 | 451 | 200 | -300 | ||||||||

| 500 | 511 | 505 | 502 | ||||||||||

| 550 | 562 | 556 | 553 | -150 | |||||||||

| 600 | 613 | 607 | 604 | ||||||||||

| 650 | 663 | 657 | 654 | ||||||||||

| 700 | 714 | 708 | 705 | ||||||||||

| 750 | 765 | 759 | 756 | ||||||||||

| 800 | 816 | 810 | 807 | ||||||||||

Contact Us

Address

High-tech Industrial Development Zone, Zhengzhou City, Henan Province, China.

jean@ji-steel.com

Phone

+86 188 3804 2177

Products

- Continuous Casting

- ● Copper Mould Tube

- ● Mould Assembly

- ● Ladle And Tundish Nozzle

- Steel Melting

- ● Graphite Electrode

- ● CPC/GPC

- ● Continuous Casting Protecting Slag

- ● Furnace Lining Vibrator

- Rolling Mill Equipment

- ● Steel Roll

- ● Tungsten Carbide Roll Ring

- ● Rolling Mill Guides

- ● Roller Table

Contact

- jean@ji-steel.com

- +86 371 6781 0168

- +86 188 3804 2177

- +86 188 3804 2177

- www.ji-steel.com

- High-tech Industrial Development Zone, Zhengzhou City, Henan Province, China.