Products

Continuous Casting Protecting Slag

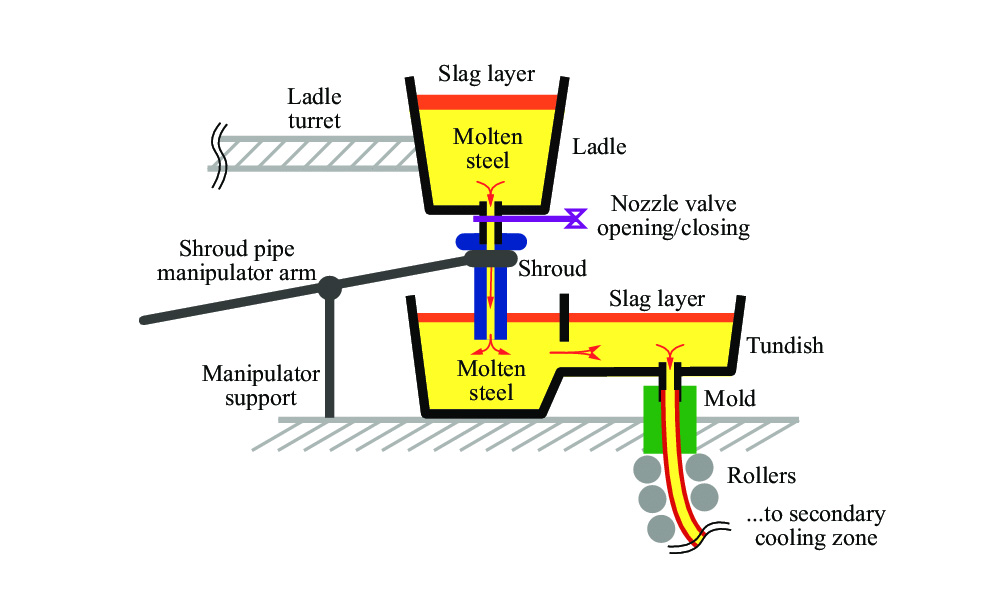

In the process of continuous casting, powder or granular slag, called Protecting slag, should be continuously added to the molten steel surface of the mold. Protecting slag is an important auxiliary material in continuous casting production. In order to achieve high quality and high efficiency in continuous casting production, and even to achieve hot delivery and hot charging of defect-free billets, the correct selection and use of mold flux is very necessary.

The Role of Protecting Slag:

1.Covering molten steel for thermal insulation;

2.Isolate air to prevent secondary oxidation of molten steel;

3.Absorb non-metallic inclusions floating on the slag interface;

4.Reduce billet drawing resistance, lubricate casting billet and mold;

5.The liquid slag flowing into the gap between the billet shell and the mold forms a slag film to control the heat transfer rate from the billet to the mold and keep the billet shell growing uniformly.

Contact Us

Address

High-tech Industrial Development Zone, Zhengzhou City, Henan Province, China.

jean@ji-steel.com

Phone

+86 188 3804 2177

Products

- Continuous Casting

- ● Copper Mould Tube

- ● Mould Assembly

- ● Ladle And Tundish Nozzle

- Steel Melting

- ● Graphite Electrode

- ● CPC/GPC

- ● Continuous Casting Protecting Slag

- ● Furnace Lining Vibrator

- Rolling Mill Equipment

- ● Steel Roll

- ● Tungsten Carbide Roll Ring

- ● Rolling Mill Guides

- ● Roller Table

Contact

- jean@ji-steel.com

- +86 371 6781 0168

- +86 188 3804 2177

- +86 188 3804 2177

- www.ji-steel.com

- High-tech Industrial Development Zone, Zhengzhou City, Henan Province, China.