Products

Ladle and Tundish Nozzle

01- Zirconium Tundish Nozzle

Information

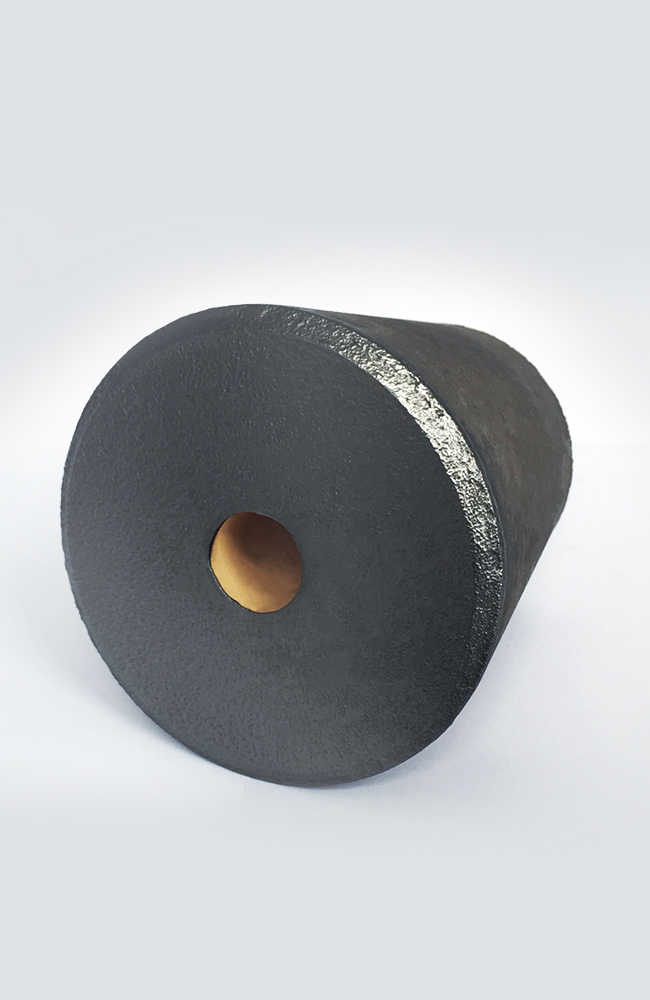

The zirconium sizing nozzle is made of stabilized zirconia and imported natural oblique zircon after being stabilized by a special process, and then formed by high-pressure molding and high-temperature firing. The nozzle model can be set according to the different steelmaking environment and use requirements of users.

Feature

This product has the characteristics of high refractoriness, good thermal shock performance, corrosion resistance, erosion resistance, small diameter expansion and long service life.

Application

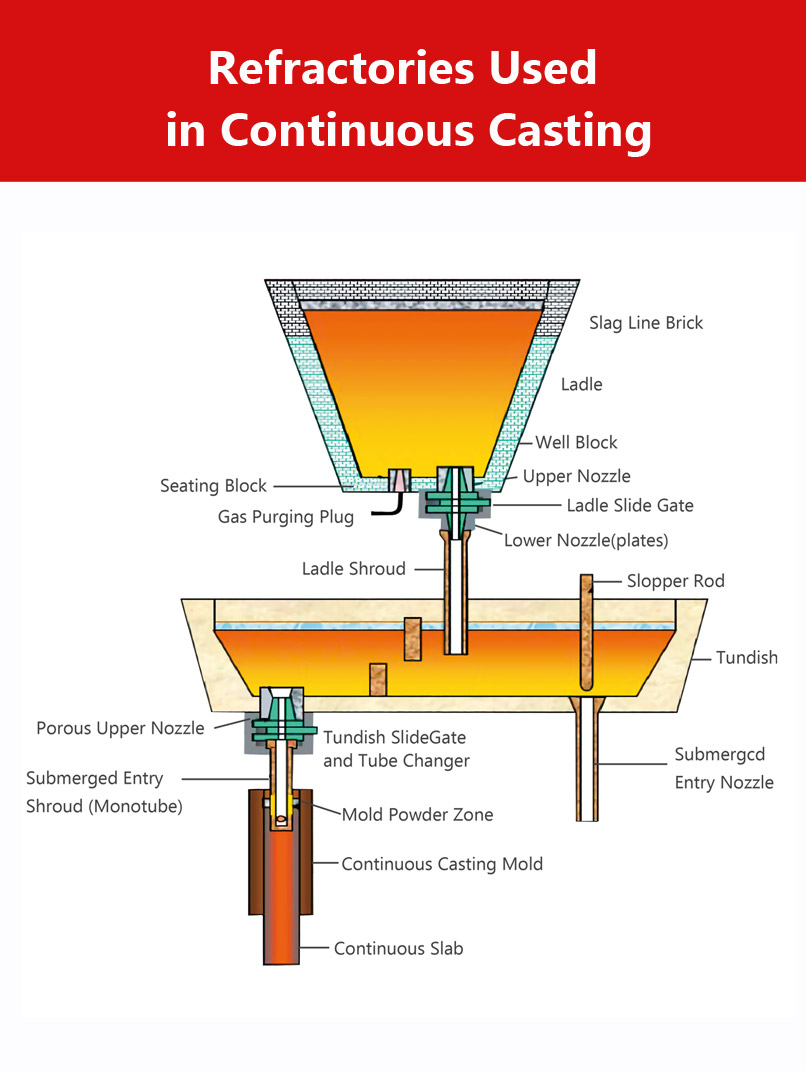

This product is mainly used for continuous casting of tundish billets, blooms, rectangular billets, and small slabs for pouring steel.

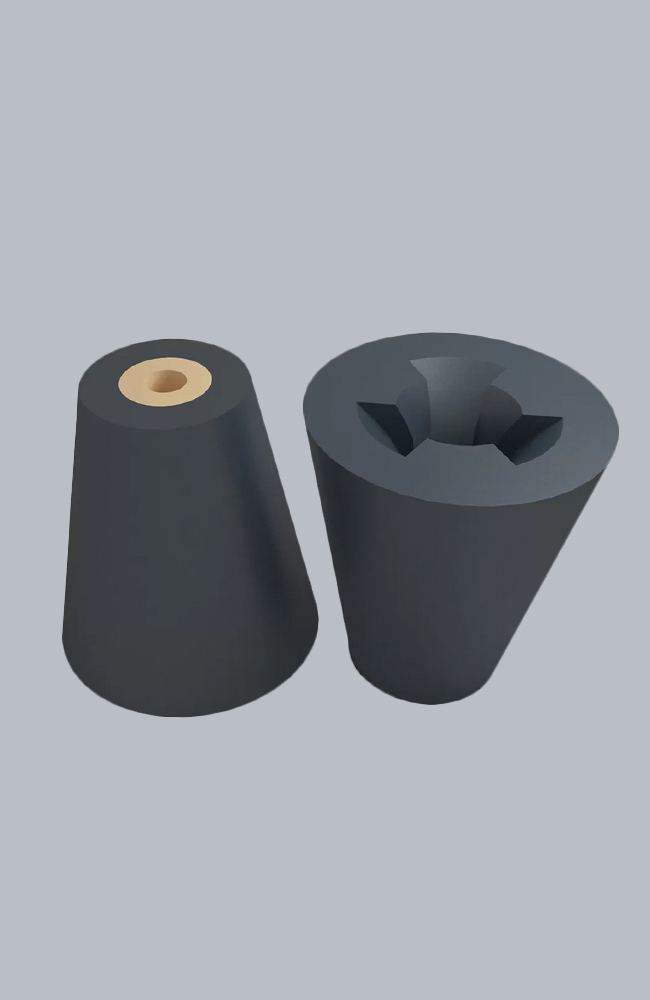

Different types of nozzle bricks

Physical and Chemical Indicators of Nozzle Inner Core

Item | SX-1 | SX-2 | SX-3 | SX-4 | SX-5 | SX-6 | SX-7 | SX-8 |

ZrO2+(Hf)O2% | ≧70 | ≧75 | ≧80 | ≧85 | ≧90 | ≧93 | ≧93 | ≧93 |

Bulk Density g/cm3 | ≧3.8 | ≧4.0 | ≧4.2 | ≧4.4 | ≧4.6 | ≧4.9 | ≧5.1 | ≧5.2 |

Apparent Porosity % | ≦22 | ≦22 | ≦20 | ≦20 | ≦20 | ≦15 | ≦13 | ≦10 |

Mpa Compressive Strength | ≧80 | ≧80 | ≧80 | ≧80 | ≧80 | ≧90 | ≧90 | ≧100 |

Thermal Shock Resistance (1100℃ cold water) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | >5 |

Physical and Chemical Indicators of External Body

| Item | W-A1 | W-A2 | W-AC3 | W-AC4 |

| Al2O3 (%) | ≧70 | ≧75 | ≧80 | ≧85 |

| C (%) | ≧3.8 | ≧4.0 | ≧4.2 | ≧4.4 |

| Bulk Density g/cm3 | ≦22 | ≦22 | ≦20 | ≦20 |

| Apparent Porosity % | ≧80 | ≧80 | ≧80 | ≧80 |

| Mpa Compressive Strength | >5 | >5 | >5 | >5 |

Ladle and Tundish Nozzle

02- Different types of nozzle bricks

Description

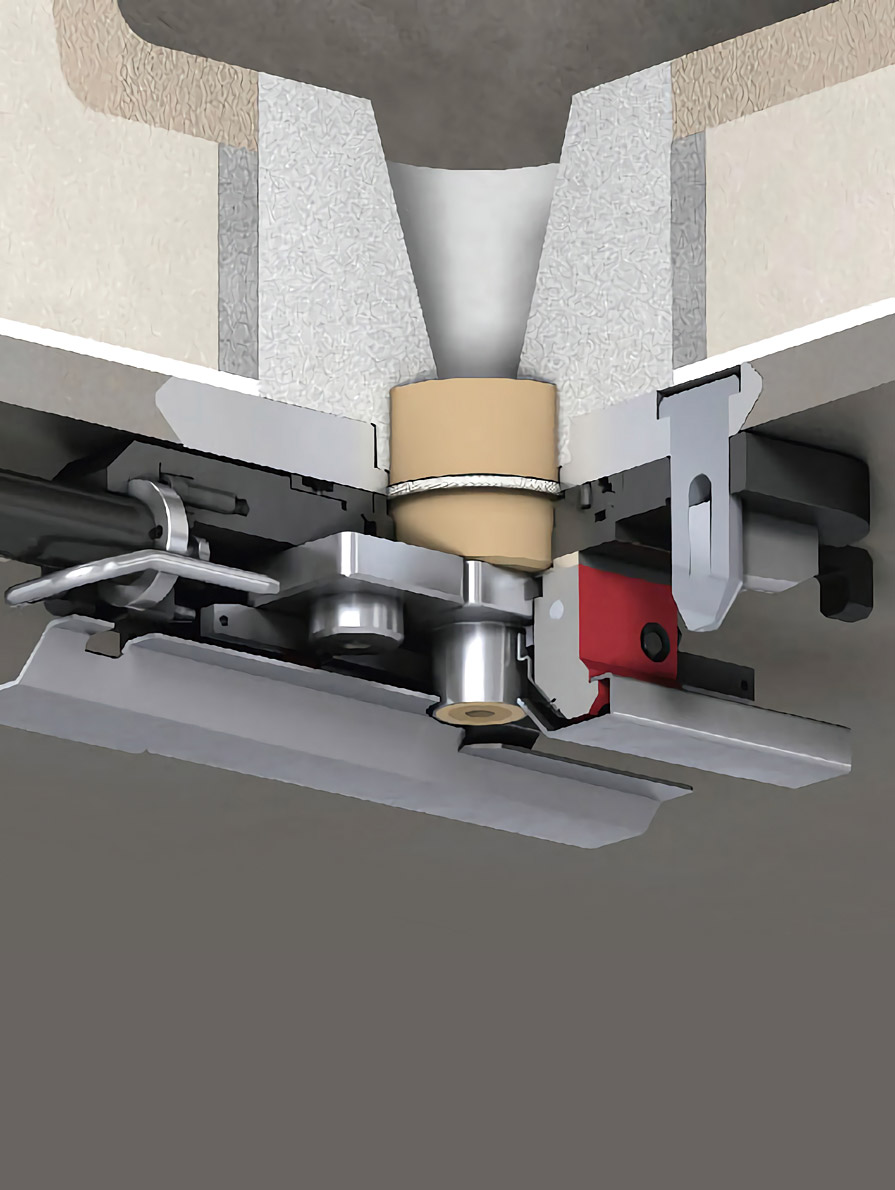

The upper and lower nozzles are composed of three parts, the outer layer is aluminum carbon, the inner core is zirconium, and the seat brick is aluminum magnesium carbon. It is formed by high pressure molding with precise process formula and assembled by high temperature firing.

Feature

The product has the characteristics of good thermal vibration stability, erosion resistance, corrosion resistance and high safety factor.

Application

The modified product is mainly used for continuous casting tundish and quick-change mechanism for pouring steel.

Physical and Chemical Indicators

| Item | Upper Nozzle | Bottom Nozzle | Base Brick | ||

Inner Tube | External Body | Inner Tube | External Body | ||

ZrO2+HfO2 (%) | ≧93 | — | ≧93 | — | — |

Al2O3 (%) | — | ≧70 | — | ≧70 | ≧65 |

MgO (%) | — | — | — | ≧10 | |

C (%) | — | ≧3 | — | ≧3 | ≧12 |

Bulk Density ( g/cm3) | ≧5.2 | ≧2.6 | — | ≧2.6 | ≧2.6 |

Apparent Strength (%) | ≦10 | ≦20 | ≦13 | ≦20 | ≦21 |

Crushing Strength (Mpa) | ≧100 | ≧45 | ≧100 | ≧45 | ≧45 |

Thermal Shock Resistance 1100℃ Cold Water | ≧5 | ≧5 | ≧5 | ≧5 | — |

Slide Gate Plate

Description

Slide Gate Plate is a key refractory material used in the ladle sliding nozzle system, mainly used to control the flow and pouring process of molten steel. It is usually made of high-performance refractory materials such as high-aluminum, zirconium or silicon carbide, and has the characteristics of high temperature resistance, erosion resistance, wear resistance and thermal shock resistance. The slide brick realizes the switch and flow regulation of molten steel through the relative sliding of the upper and lower slides, ensuring the stability and accuracy of the continuous casting process. Its performance directly affects the quality of molten steel and production efficiency, so it is required to have high strength and long service life.

Technical Data

| ITEM | Aluminum Carbon | Aluminum Zirconium Carbon | ||

|---|---|---|---|---|

| RJSLT-75 | RJSLT-80 | RJSLTG-70 | RJSLTG-75 | |

| Al2O3(%)≥ | 75 | 80 | 70 | 75 |

| C(%)≥ | 7 | 7 | 7 | 7 |

| ZrO2(%)≥ | — | — | 6 | 6 |

| BD(g/cm3)≥ | 2.85 | 3.00 | 3.10 | 3.15 |

| AP(%)≤ | 12 | 12 | 10 | 10 |

| CCS(Mpa)≥ | 80 | 100 | 120 | 120 |

Contact Us

Address

High-tech Industrial Development Zone, Zhengzhou City, Henan Province, China.

jean@ji-steel.com

Phone

+86 188 3804 2177

Products

- Continuous Casting

- ● Copper Mould Tube

- ● Mould Assembly

- ● Ladle And Tundish Nozzle

- Steel Melting

- ● Graphite Electrode

- ● CPC/GPC

- ● Continuous Casting Protecting Slag

- ● Furnace Lining Vibrator

- Rolling Mill Equipment

- ● Steel Roll

- ● Tungsten Carbide Roll Ring

- ● Rolling Mill Guides

- ● Roller Table

Contact

- jean@ji-steel.com

- +86 371 6781 0168

- +86 188 3804 2177

- +86 188 3804 2177

- www.ji-steel.com

- High-tech Industrial Development Zone, Zhengzhou City, Henan Province, China.