Products

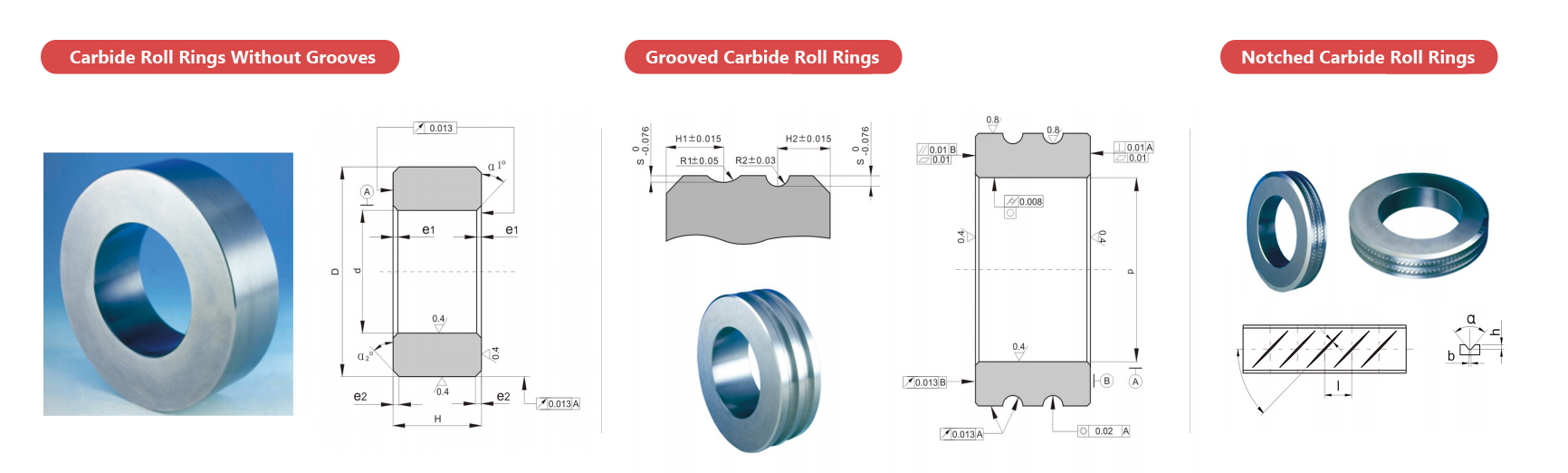

Tungsten Carbide Roll Ring

General roll rings series:Co-Ni-Cr was used as the bonding phase,with high wear resistance, corrosion resistance and versatility.

Product Induction

Compared with steel rolls,cemented carbide roll rings have the characteristics of longer life time,higher cost- effectiveness,higher dimension precision and better surface finish owning to its high hardness,good wear resistance and high modulus of elasticity,has,thus greatly reduce labor intensity and improve productivity.

With the development of China’s iron and steel industry,cemented carbide roll rings and rolls are widely used in the production of a variety of products such as wire rolling,bar rolling,tube rolling and small strip rolling and so on.

General roll rings series grades

Grade | Chemical composition Wt% | Physical properties | ||||||

WC (%) | Co+Ni+Cr (%) | Density g/cm³ | Hardness HRA | Transverse Rupture Strength N/mm² | Compressive Strength N/mm | Young modulus KN/mm² | Thermal Conductivity W/(m.K) | |

YGR20 | 90 | 10 | 14.45 | 87.5 | 3100 | 3900 | 560 | 100 |

YGR25 | 87 | 13 | 14.20 | 85.5 | 2900 | 3600 | 550 | 98 |

YGR30 | 85 | 15 | 14.00 | 84.5 | 2800 | 3400 | 540 | 95 |

YGR40 | 82 | 18 | 13.70 | 83.5 | 2800 | 3300 | 500 | 92 |

YGR45 | 80 | 20 | 13.50 | 82.0 | 2700 | 3200 | 500 | 88 |

YGR50 | 78 | 22 | 13.35 | 81.5 | 2700 | 3100 | 480 | 76 |

YGR55 | 74 | 26 | 13.00 | 79.5 | 2600 | 3100 | 446 | 66 |

YGR60 | 70 | 30 | 12.70 | 79.0 | 2600 | 3000 | 425 | 57 |

Note:

1.Typical physical &mechanical properties are listed with the variation range in accordance with the relevant national and industry standards.

2.Relevant parameters are for reference only.

Performance and Application

General roll rings series:Co-Ni-Cr was used as the bonding phase,with high wear resistance, corrosion resistance and versatility. | |

Grade | Applications |

YGR20 | High wear resistance and corrosion resistance,used in the last 1-2 stands of finishing mills. |

YGR25 | High wear resistance and corrosion resistance,used in the last 1-3 stands of finishing mills. |

YGR30 | Good toughness,wear resistance,corrosion resistance and hot cracking resistance,used in the intermediate stands of finishing mills. |

YGR40 | Good toughness and hot cracking resistance,high versatility,used in most stands of the finishing mills and in the rear stands of common mills. |

YGR45 YGR50 | Good toughness and hot cracking resistance,used in the front stands of finishing mills. |

YGR55 | Good impact resistance,used in the stands of pre-finishing rolling mills for hot rolling rebar and they can be machined by turning and milling. |

YGR60 | Good impact resistance,used for hot rolling rebar and in the first and second stands of Pre-finishing rolling mills. |

Contact Us

Address

High-tech Industrial Development Zone, Zhengzhou City, Henan Province, China.

jean@ji-steel.com

Phone

+86 188 3804 2177

Products

- Continuous Casting

- ● Copper Mould Tube

- ● Mould Assembly

- ● Ladle And Tundish Nozzle

- Steel Melting

- ● Graphite Electrode

- ● CPC/GPC

- ● Continuous Casting Protecting Slag

- ● Furnace Lining Vibrator

- Rolling Mill Equipment

- ● Steel Roll

- ● Tungsten Carbide Roll Ring

- ● Rolling Mill Guides

- ● Roller Table

Contact

- jean@ji-steel.com

- +86 371 6781 0168

- +86 188 3804 2177

- +86 188 3804 2177

- www.ji-steel.com

- High-tech Industrial Development Zone, Zhengzhou City, Henan Province, China.